A sudden power failure in a Brendale factory or a Virginia warehouse doesn’t just halt work; it costs you time, money, and can pose a serious fire risk. For industrial businesses across North Brisbane and the Moreton Bay Region, electrical faults are the silent killers of productivity.

With the mix of older industrial sheds in Redcliffe and newer manufacturing facilities in Narangba and Clontarf, electrical systems are often under stress from modern, heavy machinery. You need to know the signs before a small issue becomes a catastrophic failure.

This guide reveals the Top 5 Electrical Issues threatening your operation and teaches you the simple, crucial signs to spot them.

Issue #1: The Overloaded Circuit (The Hidden Heater)

The Problem: A circuit’s job is to carry a specific, safe amount of electricity. When a business adds too many high-draw appliances (like welders or new air compressors) without upgrading the circuit’s wiring, the circuit is overloaded. Too much demand on a wire causes it to heat up like a stove element, which melts insulation and risks fire.

Spotting the Signs:

- Frequent Tripping: The same circuit breaker trips all the time.

- Warm Components: Outlets, plugs, or the wiring near the switchboard feel warm or hot to the touch.

- Dimming Lights: Lights dim or flicker when heavy machinery turns on.

Sample Case Study Scenario: The Brendale Logistics Hub

A rapidly growing logistics company in Brendale installed three new packaging machines without consulting an electrician. The machines were all plugged into power points on the same circuit. The high power draw caused the wiring insulation inside the wall to melt. The issue was only found when a worker reported a “faint smell of melting plastic” near the wall, preventing a significant fire. The electrician fixed the damaged wiring and installed two new, dedicated circuits.

Issue #2: Faulty Wiring and Loose Connections (The Fire Starter)

The Problem: In industrial settings, vibration from heavy machinery, heat cycles, or simple age can make connections loose. A loose connection causes electrical resistance, which generates massive heat and leads to arcing—where electricity jumps the gap—creating sparks and a high fire risk.

Spotting the Signs:

- Buzzing or Sizzling: Unusual noises from power points, switches, or the switchboard.

- Flickering Lights: Lights flicker, especially after movement or vibration near the circuit.

- Scorch Marks: Brown or black marks around a switch or power point, indicating overheating.

Sample Case Study Scenario: The Old Shed in Clontarf

An older manufacturing shed in Clontarf was due for an inspection. The owner noticed that a small section of lights had started flickering. The electrician used a thermal imaging camera during the inspection and found a connection deep inside the main distribution board was running 40 degrees hotter than the rest. This ‘hot spot’ was a loose, arcing connection. Tightening the termination bolt prevented a high-risk short circuit that could have shut down the entire facility.

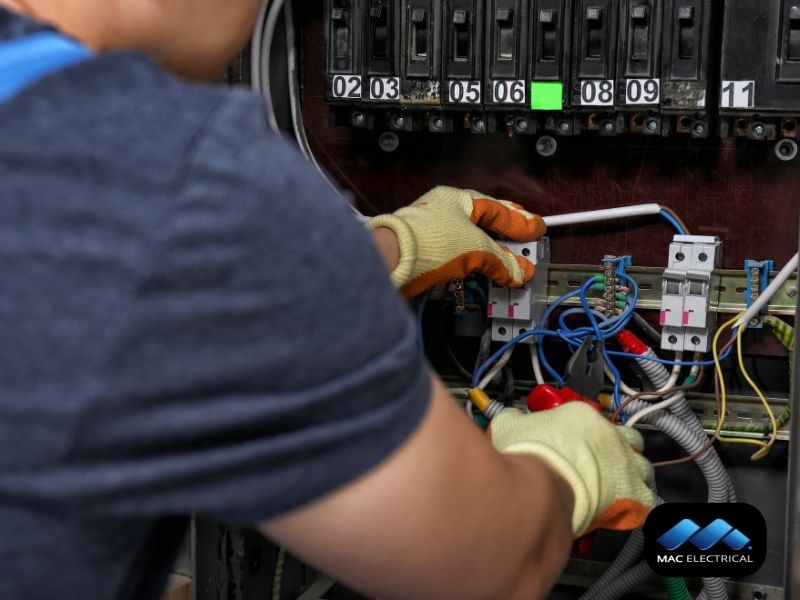

Issue #3: Aging Switchboards and Electrical Panels (The Power Failure Hub)

The Problem: Your switchboard is the control centre. If it’s old, it might use outdated parts (like old fuses) and often lacks the capacity to handle modern power demands. Corrosion from the coastal humidity in areas like Redcliffe also takes its toll.

Spotting the Signs:

- Visible Damage: Rust, corrosion, water streaks, or melted components on the exterior or interior.

- Vermin: Open holes where cables enter, allowing geckos or rodents inside (a common cause of short circuits in QLD).

- Constant Warmth: The panel or board always feels warm or hot to the touch, even when the facility isn’t running at full load.

Sample Case Study Scenario: The Redcliffe Gecko Incident

A marine maintenance plant near Redcliffe experienced a loud bang and total loss of power to one key section. The investigation found that the main switchboard cabinet had an unsealed cable entry point. A small gecko had entered, bridged the gap between two live components (active and neutral), and caused a massive, expensive short-circuit, destroying the internal breaker module and resulting in a multi-day shutdown.

Issue #4: Power Surges and Voltage Fluctuations (The Equipment Killer)

The Problem: A power surge is a sudden, brief spike in voltage that can fry the sensitive electronic controls, circuit boards, and memory in your modern industrial machinery. Surges can come from outside (like lightning or grid problems) or inside your facility (like a large motor switching on).

Key Indicators:

- Equipment Resetting: Computerised machines or PLCs randomly restart or show error codes.

- Short Lifespan: Electronic devices, power supplies, or light ballasts fail often and unexpectedly.

- Scorched Devices: Small scorch marks on power boards or the back of electrical plugs.

Sample Case Study Scenario: The Virginia Control System

A logistics firm in Virginia was frequently hit by local storms. Over two years, they had to replace several expensive Programmable Logic Controllers (PLCs) and a key server’s power supply due to component failure. They finally installed a Whole-of-Site Surge Protection Device (SPD) at their main switchboard. Since the upgrade, they’ve had zero equipment damage claims related to lightning or power spikes.

Issue #5: Non-Compliant Safety Switches (RCDs) (The Life Saver)

The Problem: RCDs (Residual Current Devices), commonly called safety switches, are a legal requirement under the Electrical Safety Act 2002 (Qld). They save lives by cutting power in milliseconds if a person touches a live wire, preventing a fatal electric shock.

Spotting the Signs:

- None Installed: You can’t see RCD switches covering all power and lighting circuits on your main board.

- Not Tested: The RCD switch doesn’t have a visible test tag with a recent date (they need regular testing).

- Trip Failure: When you push the ‘Test’ button on the RCD, it fails to immediately trip the circuit.

Case Study Scenario: WorkSafe QLD Penalty

In a relevant Queensland Magistrates Court case, a PCBU (Person Conducting a Business or Undertaking) was fined significantly for multiple electrical safety breaches, including failure to comply with the Wiring Rules. Crucially, failing to ensure circuits have adequate shock protection like tested and functional RCDs is a serious breach (Category 2) under the Electrical Safety Act 2002. The risk of exposing workers to potential electric shock, even if no injury occurred, warranted a severe financial penalty.

Your Action Plan: What North Brisbane Businesses Must Do

Don’t wait for smoke or a total blackout to act. Follow these steps:

Immediate Action:

If you smell burning, see smoke or sparks, or hear a loud buzzing noise, switch off the power to that circuit immediately (if safe to do so) and call a professional North Brisbane electrician.

The Proactive Fix (Thermal Scanning):

Question: How often should a Brisbane industrial switchboard be thermally scanned to check for hot spots?

Answer: Most industrial insurance companies recommend an annual thermal imaging scan. This uses a special camera to see heat caused by loose connections or overloaded wires before they fail.

Compliance Check:

Question: What is the required testing and tagging frequency for portable electrical equipment in a high-risk workshop like one in Narangba?

Answer: Under WHS laws, this equipment must be inspected, tested, and tagged by a competent person. For high-risk areas, this is usually every 3 to 6 months.

Other Questions

Why is my power bill so high if nothing is failing?

High power bills can be a sign of inefficiency caused by old equipment or poor power quality. Issues like low power factor (meaning you’re wasting energy) can be fixed with modern switchboard equipment, often saving you money!

How long does a commercial electrical inspection take?

It depends on the size of your facility, but a standard full inspection including thermal imaging and RCD testing can often be done in half a day to a full day. It’s quicker and cheaper than recovering from a major fault!

What is ‘Test and Tag’ and do I really need it?

Yes, you do! Test and Tag is when an electrician visually checks and electronically tests portable equipment (like power tools and extension leads) to make sure they’re safe. It’s a key part of WHS compliance for Australian workplaces.

Is my business required by law to have RCDs?

Yes. In Queensland, safety switches (RCDs) are legally required on all circuits in commercial premises where power is supplied. It’s not just a good idea; it’s the law that protects against electric shock.

What We Have To Say

Stop risking costly downtime and massive repair bills. By knowing the Top 5 Issues and the simple signs they give off, you can move from reacting to problems to preventing them. As trusted local experts serving Clontarf, Brendale, Narangba,Virginia, Redcliffe, and all of North Brisbane, Mac Electrical QLD is ready to secure your facility.

Contact Mac Electrical QLD today to book your Commercial Electrical Health Check and get your business up to Australian safety standards. Your peace of mind and your bottom line will thank you for choosing local expertise!

0 Comments